Remote Resident Stephen Hawes on the Benefits and Future of Digital Manufacturing

Lifelong maker Stephen Hawes is no stranger to electronics and digital fabrication. He participated in the Connecticut Invention Convention in elementary school and was featured on both The Tonight Show with Jay Leno and The Martha Stewart Show because of his inventions. In high school, he was doing freelance web design, and in college he bought his first digital fabrication tool and delved deeper into electronics design. He even founded a prosthetics company, Atlas Laboratories, in 2016 and received a $10K grant to develop his ideas further. Stephen has clearly been on this upward trajectory for years now. He currently resides in Boston and works for Formlabs.

Stephen has been on our radar for his work with the Bantam Tools Desktop PCB Milling Machine from the earlier days, so he was the perfect candidate to be our inaugural Remote Resident. We chatted with him to learn more about his favorite tools, his workshop, and what he thinks is the future of digital fabrication.

How did you first get started with digital fabrication? When did you first use the Bantam Tools mill?

I first got started with digital fabrication when I pulled the trigger on a 3D printer back in college. The ease of designing a part, then having a machine create it for you instead of having to fabricate it yourself was pretty incredible. I first used a Bantam Tools mill when I was working for a company called Deeplocal. There, I had to make functional prototypes in incredibly short timelines, which meant ordering PCBs was out of the question. We milled dozens of boards in order to get projects out the door, and I really developed an appreciation for fabbing PCBs in-house.

What are your favorite types of projects to make?

I love projects that include a bit of everything: mechanical, electrical, and software design. Each discipline is satisfying on its own, but making them work together fluidly is really a blast.

What has the Bantam Tools mill enabled you to do that you previously couldn’t?

It’s allowed me to prototype circuit boards in about 5% of the time that it used to take. Traditionally I’d make a design and send it out to a board shop, then sit on my hands for a couple of weeks until they arrived. If my design was wrong, I’d make an edit and wait another two weeks. Now that entire process happens in a day.

What’s your favorite feature of the Bantam Tools mill?

I don’t have to think about the process. The Bantam Tools mill and software serves as a black box in my mind; I put a file in, and I get a PCB out. When I’m prototyping, I want all my mental resources allocated to that design process, not testing feeds and speeds or trying to remember Grbl commands. The mill removes all that from the process and lets me focus on what I’m building. The best tools are the ones that get out of your way.

Aside from the mill, what are three tools you can’t live without?

1. Flush snips: Four bucks gets you a great set that are fantastic for cutting/stripping wire, cleaning 3D prints, and just generally cutting things in a very precise way. I have three!

2. Omnivice: I recently pulled the trigger on one and I’m in love. It’s incredibly hefty, so you can really push or pry on a PCB and it’s not going anywhere. The huge dial on the top is super easy to manipulate, so getting boards in and out is super quick.

3. A 3D space mouse: I got one a few years back, and it’s the bee’s knees. I know it’s a point of contention for many due to the steep learning curve, but from my experience, it’s worth putting in the time to learn. It’s just so fast.

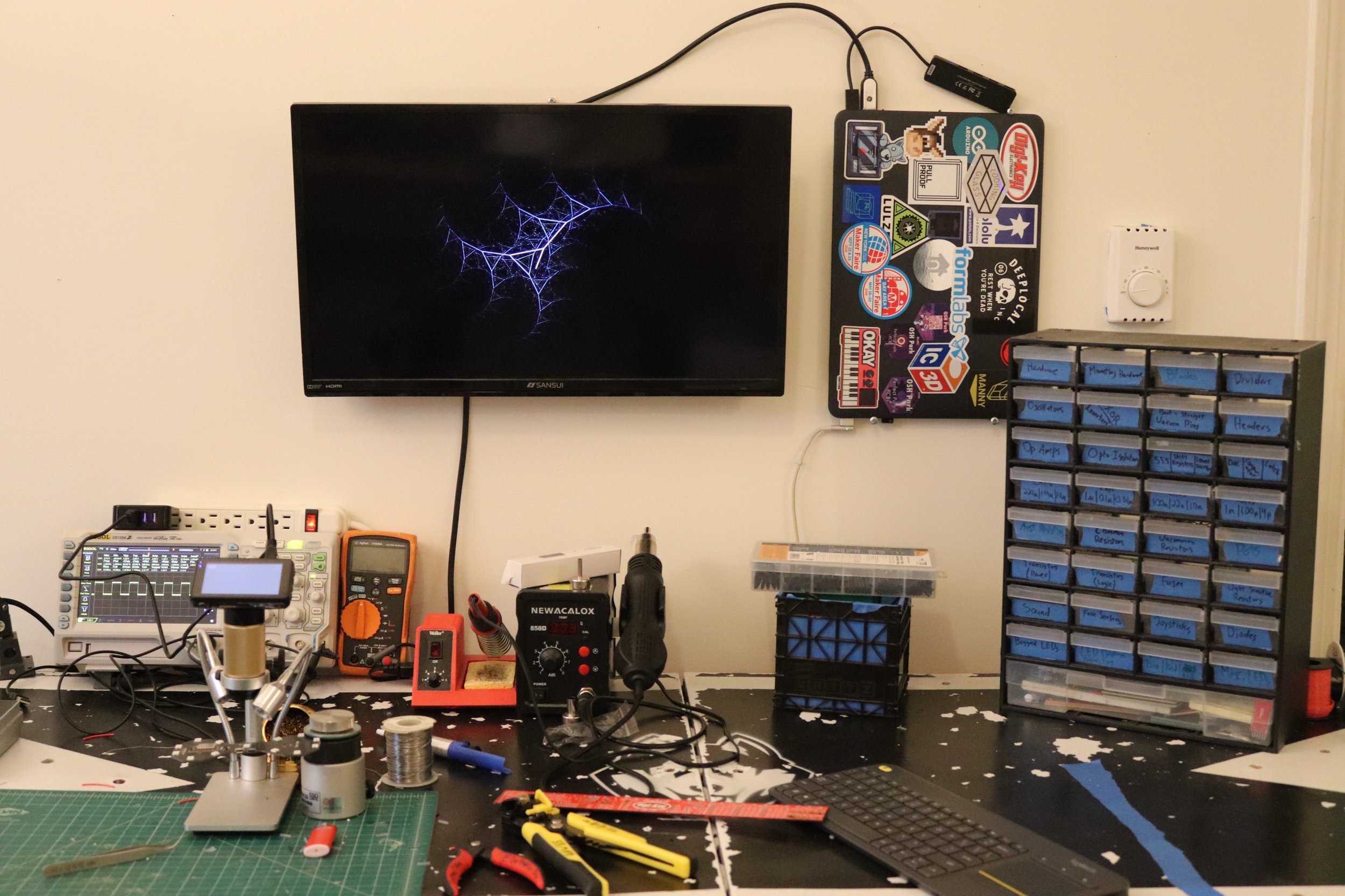

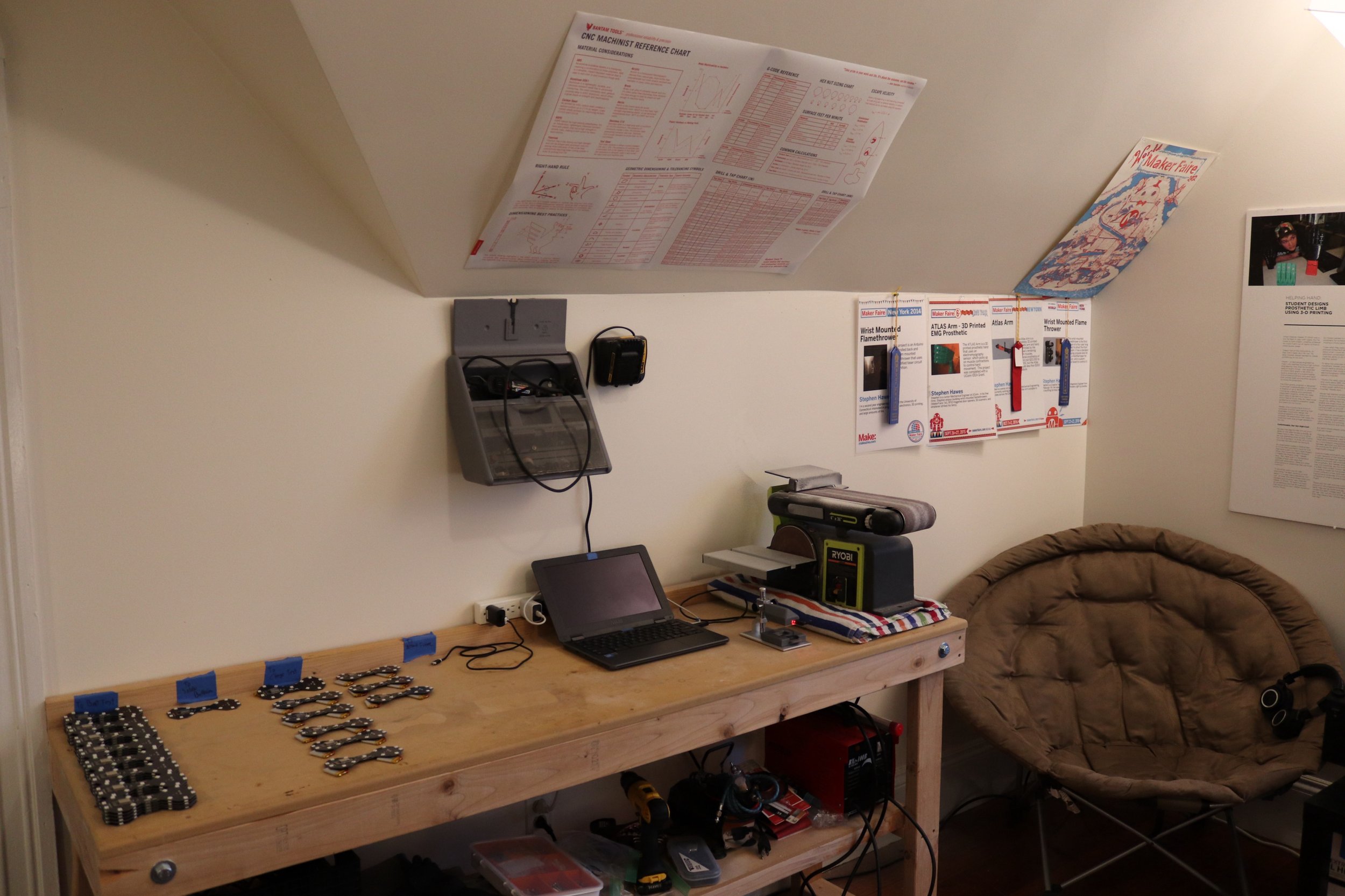

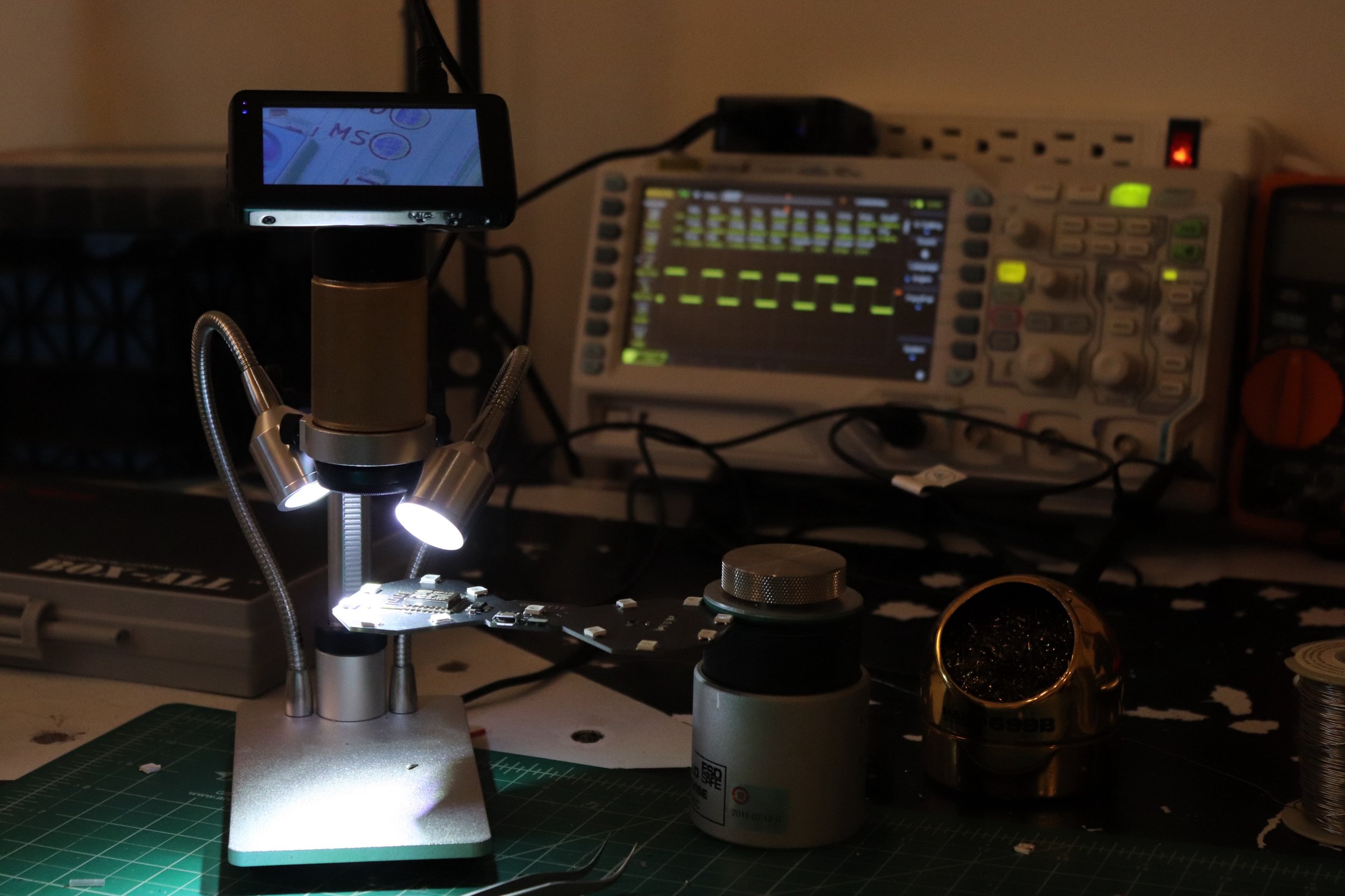

Describe your workshop.

It’s my favorite room in the house! I have dedicated areas for software, electronics, and physical builds. I want to be able to make a prototype of almost anything without leaving the workshop. Everything is always plugged in, so using a tool is as easy as picking it up. All the lights are voice-controlled, which is great for shooting my YouTube videos. I don’t have to run all around my workshop adjusting lights; I can just say what I want, and it magically happens!

What was your most epic fail and what did you learn from it?

I’ve had a lot of epic fails, but the one that stands out was with a recent project. It’s a light-up bowtie you control over wi-fi called the Glowtie. In early versions, it would randomly disconnect from wi-fi for no apparent reason. After tons of research and consulting with friends, I discovered that when the controller sent a signal to turn on the lights, the lights pulled so much current that there wasn’t enough left for the controller. It was killing itself! I learned to always give myself a hearty factor of safety for power consumption.

What advice do you have for folks who want to get into digital fabrication?

Try it! It makes building things so much easier. It might be possible to make a circuit board, plastic part, or vinyl decal by hand, but the quality of life and quality of the part are so much higher when using digital fabrication. Prices for machines are more accessible than they’ve ever been, and incredibly supportive communities around them are growing larger every day. Not to mention, having an army of robots building parts for you is pretty darn awesome!

Who’s someone in the digital fabrication field you admire?

I greatly admire Andrew (bunnie) Huang. Although his focus is more in large-scale manufacturing, he leverages digital fabrication on the production line. He likes to understand the process behind how things are made and get involved in a more hands-on way than most.

What’s your vision for the future of digital fabrication?

I subscribe to the notion that things are either a tool or a project: a tool being something you interact with purely for the end result it provides, where a project is something that requires you to delve into the process of its operation. At first, digital fabrication tools were more like projects; they sometimes required hours of tuning and weren’t reliable. To use one was to be invested in the process enough that you were willing to spend time debugging problems.

But now, digital fabrication has gotten so much more reliable that I view it as more of a tool. When I run a job on the mill, I’m not concerned about if it’s going to finish — it just works. And 3D printers are seeing a similar movement towards reliability. I’m expecting a future where digital fabrication tools are not only ubiquitous, but also taken for granted just as much as your computer.

Follow Bantam Tools on Instagram, Facebook, Twitter, and be sure to subscribe to the Bantam Tools mailing list to receive more content like this.