High School Robotics Team Levels Up Their Bots with CNC-Milled Aluminum Parts

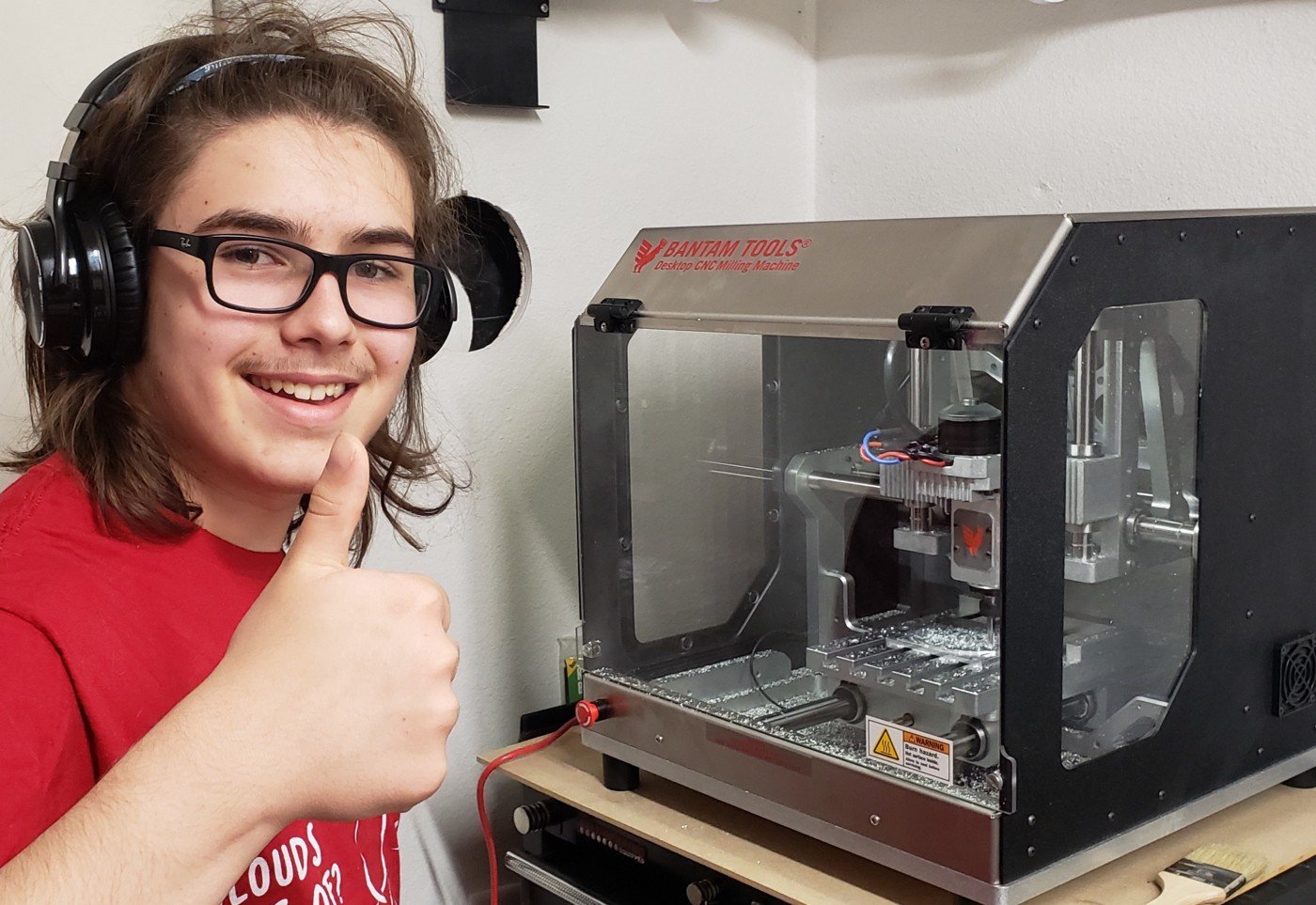

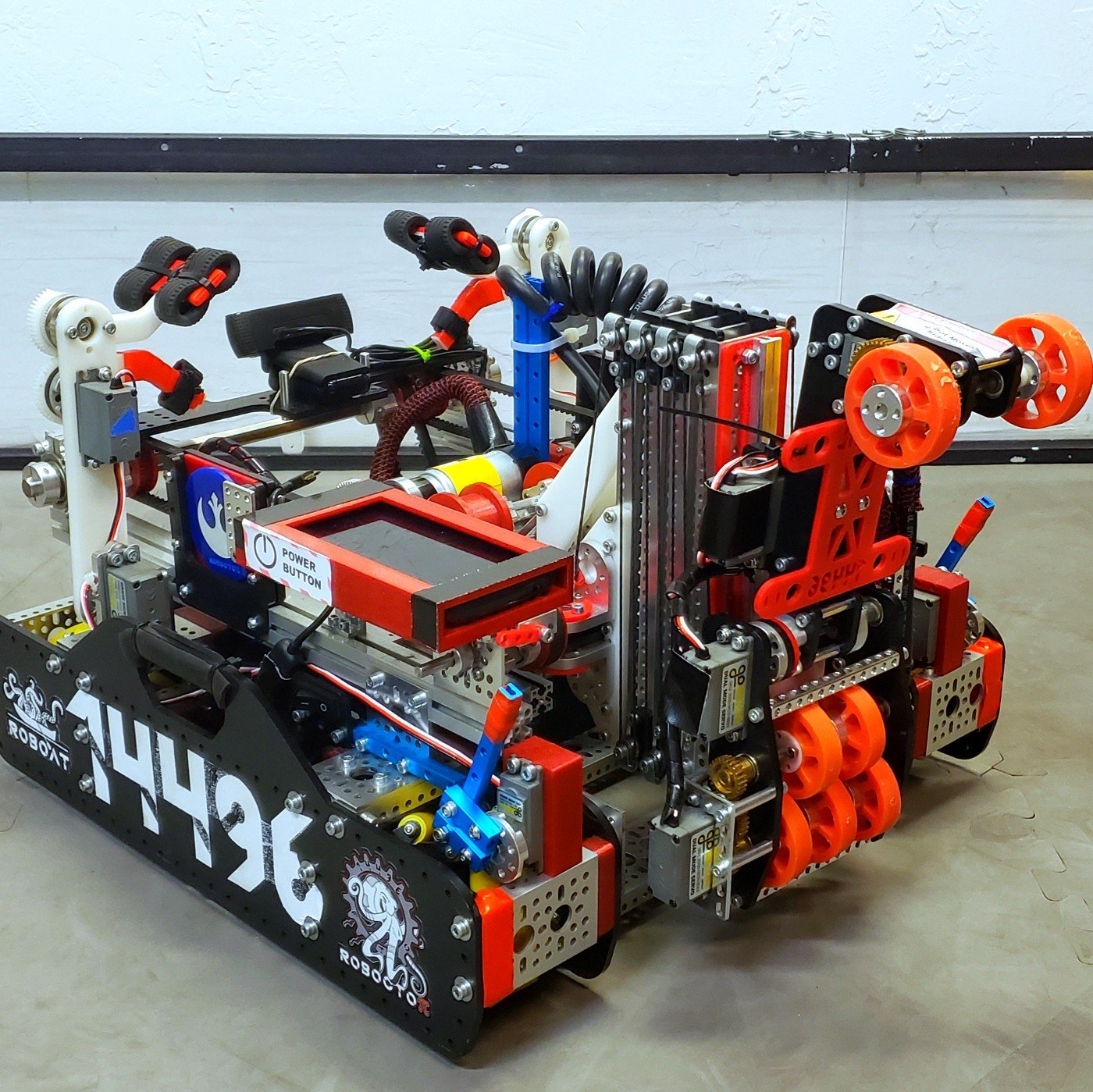

Escondido, California-based high school robotics team Roboctopi caught our eye with their sleek aluminum robot parts they posted on Instagram. Earlier this year, they added ourBantam Tools Desktop CNC Milling Machine to their tool arsenal, meaning they could now incorporate precise, durable custom aluminum parts in their robots. In a nutshell, the competition had better watch out. We caught up with them to learn more about their team, tools, and build processes.

Tell us more about the FIRST Tech Challenge and the Roboctopi team. Also, we have to know: Where did the name come from?

Hello! We’re Team Roboctopi, a high school community robotics team in Escondido, California, competing in FIRST Tech Challenge (FTC). We currently have eight students and three adult mentors from three school districts. We’ve spent the past three years building our skills by participating in FIRST Robotics.

FIRST Tech Challenge teams are challenged to design, build, program, and operate robots to compete in a head-to-head challenge, in an alliance format. Guided by adult coaches and mentors, we develop STEM skills, including engineering design principles and CAD (computer-aided design). This helps us learn the value of hard work, innovation, and working as a team.

hrough the program, we’ve been able to:

Learn advanced programming principles using Java and AI neural networks.

Practice presentation and interview skills while presenting our ideas.

Learn documentation principles through our detailed engineering notebook.

Practice marketing through our social media and fundraising channels.

Improve our community by organizing, attending, and promoting STEM events in our community.

Prior to forming Roboctopi, we participated in FIRST Lego League under the name Technimals. We sort of became known as the team with an unpronounceable name, so we thought we should carry on that tradition when we came up with Roboctopi. We’re also well known for dropping a lot of puns, so the name works on multiple levels. The correct pronunciation is row-boc-toe-pie, in case you were wondering.

What made you want to add CNC machining to your workflow? Has the team used CNC machines prior to the Bantam Tools Desktop CNC Milling Machine?

As an independent high school robotics team, we’re always looking for sponsors to provide money, materials, or tools. We’ve been very fortunate to have a mentor who’s willing to provide access to a laser cutter and Bantam Tools Desktop CNC Milling Machine, and we’ve had several 3D printers we’ve either purchased or salvaged and repaired.

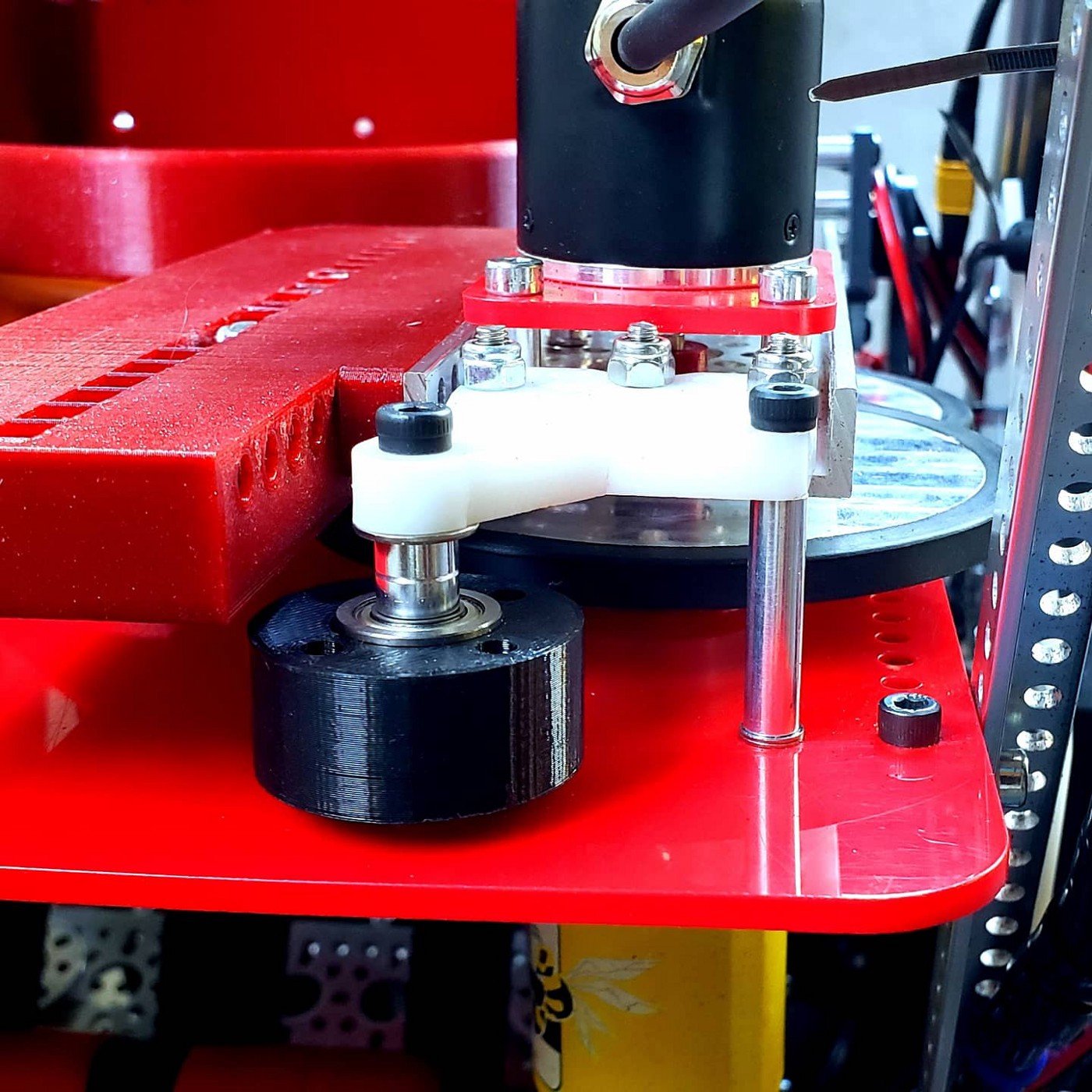

We use the laser cutter for as much as we can because it’s extremely fast, so we can iterate and test multiple designs quickly. We typically test designs in wood to reduce cost until we’re happy with performance, then we redo plates in Delrin for strength. The 3D printers are primarily used for mechanical parts we can’t laser cut, but it takes a long time to print parts, so it requires more lead time and planning.

Also, our robotics season is around six months with multiple league competitions, so our robot takes a lot of abuse and iterative updates as we gather data on our performance. Parts that are 3D printed often break during competition, so we have to print lots of spare parts.

We’ve wanted to be able to quickly fabricate in metal for a while. It really opens a lot more possibilities for us to design mechanisms that are robust and reliable. There’s only so much you can do with hand tools and drills. Having a highly accurate and repeatable fabrication tool, with excellent guides, great software, and support, allowed us to learn and integrate it quickly.

The Bantam Tools Desktop CNC Milling Machine fits all those requirements. It’s an amazing tool to work with.

You’ve been milling a ton of aluminum parts for your robot using the machine. Is this primarily what you use the machine for or do you use it to machine other materials and projects?

We can’t reveal some of the things we’ve been doing yet, but there’s amazing stuff in development for this coming season. Right now, it’s exclusively being used for fabricating aluminum components for our robots. Our mentor has been kind enough to give us access to his lab and tools, where the laser and mill are located. Ideally, we’d love to have a Bantam Tools Desktop CNC Milling Machine located in our secret lair so we could learn, experiment, and manufacture during late night practices, but we’re thankful to have access at all.

We still have a lot to learn about CAM (computer-aided manufacturing), machine tooling, and speeds and feeds. There’s so much to absorb, but the Bantam Tools software and guides made it easy to go from complete novices to making our own precision metal parts within days of receiving it.

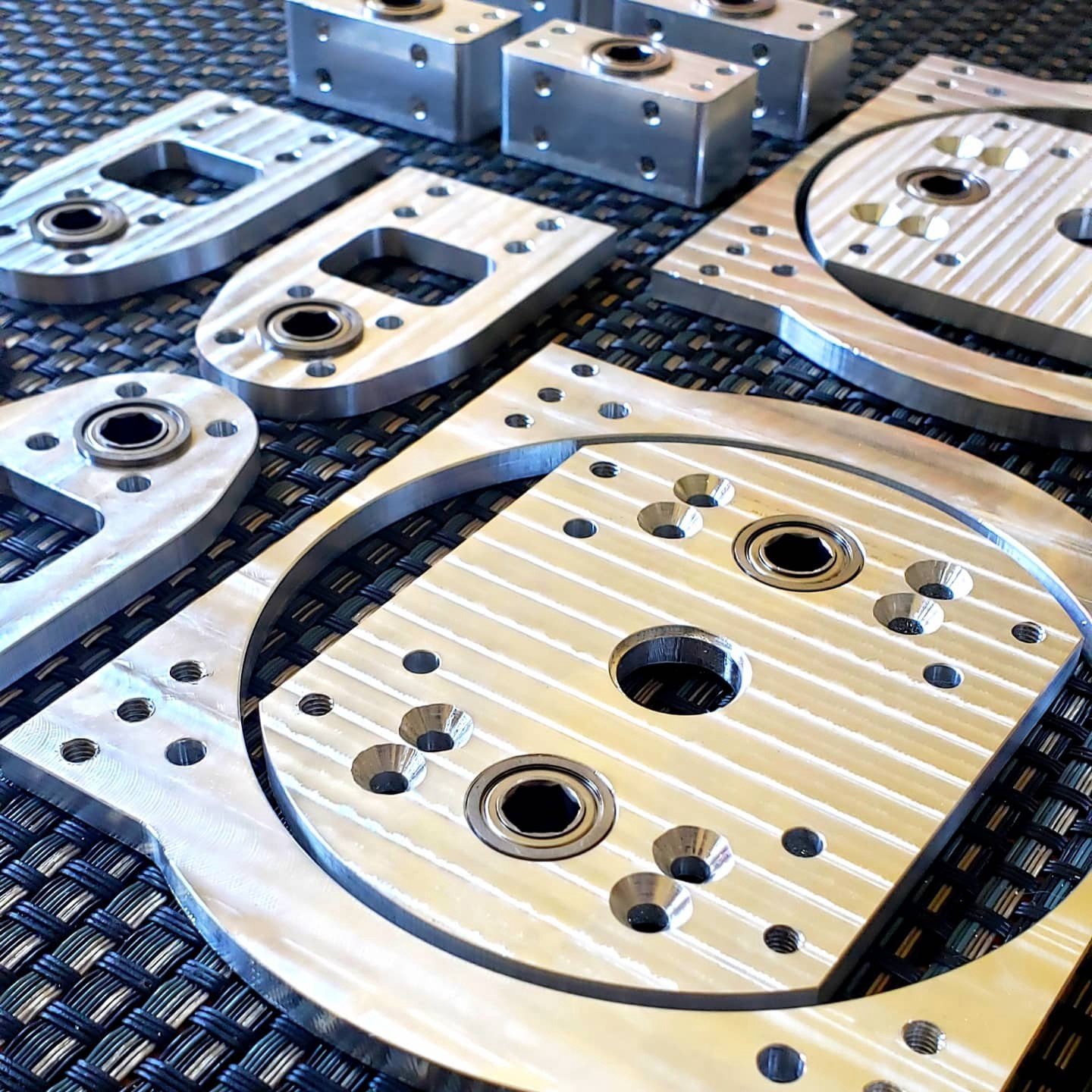

The design process and requirements for subtractive milling are also subtly different. We design parts differently for the mill then if we were going to 3D print or laser cut them. As we learn and gain experience, we’ll begin fabricating things not related to robotics. For now, we’re making great use of it to manufacture bomb-proof aluminum robot parts.

We also use a ton of laser-cut Delrin, so we’ll start experimenting with milling more complex features in that material soon. We love working with Delrin because it’s strong and has a low coefficient of friction, which makes it ideal for things that need to slide or rotate. We’re interested in using brass in the future for items that require more mass or better friction properties, like flywheels and bushings.

Do you use other digital fabrication tools in your creative process? If so, where does the Bantam Tools Desktop CNC Milling Machine come in?

We’re very comfortable designing in CAD and using digital fabrication. Having highly repeatable fabrication tools is essential when you need to accurately make multiple copies of the same part. We were already using Fusion 360 for design, so learning how to program CAM in Fusion 360 has been straightforward. The software and UI for the Bantam Tools Desktop CNC Milling Machine are well thought out and easy to navigate. Anyone with experience using a slicer for 3D printing would have no problem finding their way around.

Our mentor taught us how to use his laser cutter all the way back during our FIRST Lego League (FLL) team days. Our first project was a Bluetooth-enabled smart planter that pulled water from the air using a Peltier system. We designed the planter in 2D using Inkscape and did test cuts in cardboard to make sure it fit together. We made the final product using acrylic and won FIRST Place Science Presentation at the FLL Southern California Regional Championship. Since then, we’ve become experts in CAD, laser cutting and 3D printing. Our engineering mentor introduces us to new concepts and techniques every year, so we continue to learn and add complexity to our engineering process.

The Bantam Tools Desktop CNC Milling Machine has added more advanced fabrication and stronger, more reliable parts. It’s also a lot faster than 3D printing, which was a nice surprise. We’ve already started designing parts that would’ve been impossible due to strength requirements before. There’s a lot of parts buried deep inside our robot that are a pain to replace or repair. Fabricating in metal will allow us to be sure some critical component doesn’t break in a place that’s impossible to repair during a competition.

What has the Bantam Tools Desktop CNC Milling Machine enabled you to do that you previously couldn’t?

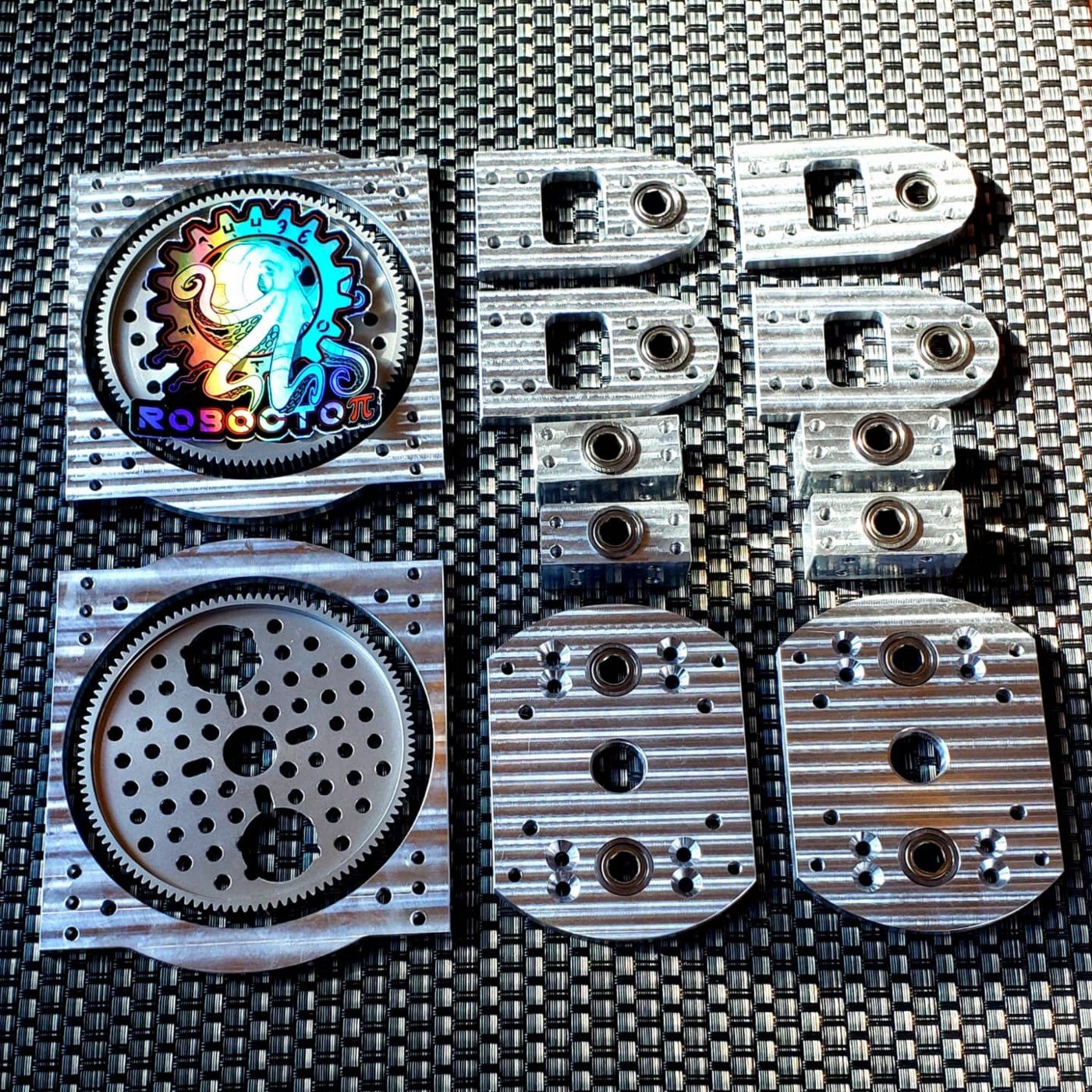

The first thing we made last season on the mill were some aluminum fly wheels for our disc shooter. The added mass had a huge impact on our accuracy. Due to space requirements, there was no other option to add mass on those. We also replaced some plastic shaft brackets — that were causing us to constantly break expensive shaft hubs — with aluminum. They worked beautifully and saved us a bunch of time and money.

This year, we’re working on some radical new systems that handle huge torque loads that would never have been possible with plastic or wood parts. Having a precise repeatable way to make things quickly in house also allows us to test, iterate, and improve ideas rapidly. Our team is very agile, so we burn through ideas and constantly update components and even entire sub-systems as we learn, observe, and gather performance data during the season. Sometimes ideas and designs don’t work the way we expected, and we must adapt or start over. The Bantam Tools Desktop CNC Milling Mahine is allowing us to do things we thought were impossible last year.

What’s your favorite feature of the Bantam Tools Desktop CNC Milling Machine? What about the Bantam Tools software?

Definitely the software probing routines and feature location. It’s so easy to make parts that require multiple setups. As novice machinists, we’ve heard it can be quite challenging to align and locate multiple operations on different sides and maintain precision. So far, we haven’t found that to be the case. It’s been quick and easy. We’ve also started using the Bantam Tools Desktop CNC Milling Machine to precisely modify existing parts from other vendors. It’s great being able to add a hole or a slot to an existing part. That’s opened a lot of new design possibilities.

It’s much easier to modify existing things with precise, repeatable milling and feature location. Teams need to modify parts often to improve performance and stay ahead of the competition. With the Bantam Tools Desktop CNC Milling Machine, it’s quick, precise, and clean. We also love that it’s fully enclosed. Nobody wants dust and aluminum chips contaminating their lab. Cleaning up after is easy.

The getting-started projects and software are amazing. They made it super easy to learn how to use the machine and the process of milling. Did we mention how friendly and encouraging your staff has been as well?

Aside from the Bantam Tools Desktop CNC Milling Machine, what are three tools the team can’t live without? Why?

The Datron single-flute tools are our go-to for machining aluminum. They’re amazing. The templates provided for speeds and feeds have made it easy to adapt them to new operations.

We use a lot of Nitto tape to hold things down. Fixturing is key to getting good results. We’d love to try out the fixturing pallet and vises you recently released.

We also highly recommend the deburring tool set on your website to remove sharp edges. Really essential piece of kit. Safety first.

On the topic of safety, we want to mention how important correct PPE and cleaning and maintenance is. Always wear safety goggles — always. Use gloves and a mask when handling aluminum chips and dust. Inspect the machine and tools every time, and leave the machine clean and clear of chips and debris after every use. Make sure to have a safety plan before something goes wrong (eye wash, first aid).

What are three tips you’d offer machinists or designers using the machine for the first time?

Follow the getting started tutorials and projects. There’s so much to learn, and Bantam Tools has made it so easy to get started. We watched all the blog videos as well. When you start making your own projects, start simple and add complexity as you learn. Our first items were essentially flat plates with pockets. Now we’re making parts with features on all sides, with multiple setups.

Also, the Bantam Tools staff are super helpful and friendly. If you have a question or run into a problem, contact them. They’re amazing.

One last thing: Share what you’re working on through social media or forums so others can learn and be inspired. We’re always delighted when someone contacts us to ask us about what we’re doing or for advice on how we did it. We learn better together. Help build a friendly, inclusive community!

At Bantam Tools, we build desktop CNC machines with professional reliability and precision to support world changers and skill builders. For the latest Bantam Tools news, sign up for our newsletter. If you’re interested in adding a Bantam Tools machine to your workflow you can order directly from our online store or request a quote.