Charlotte Latin School Has is Closing the Skills Gap with Bantam Tools

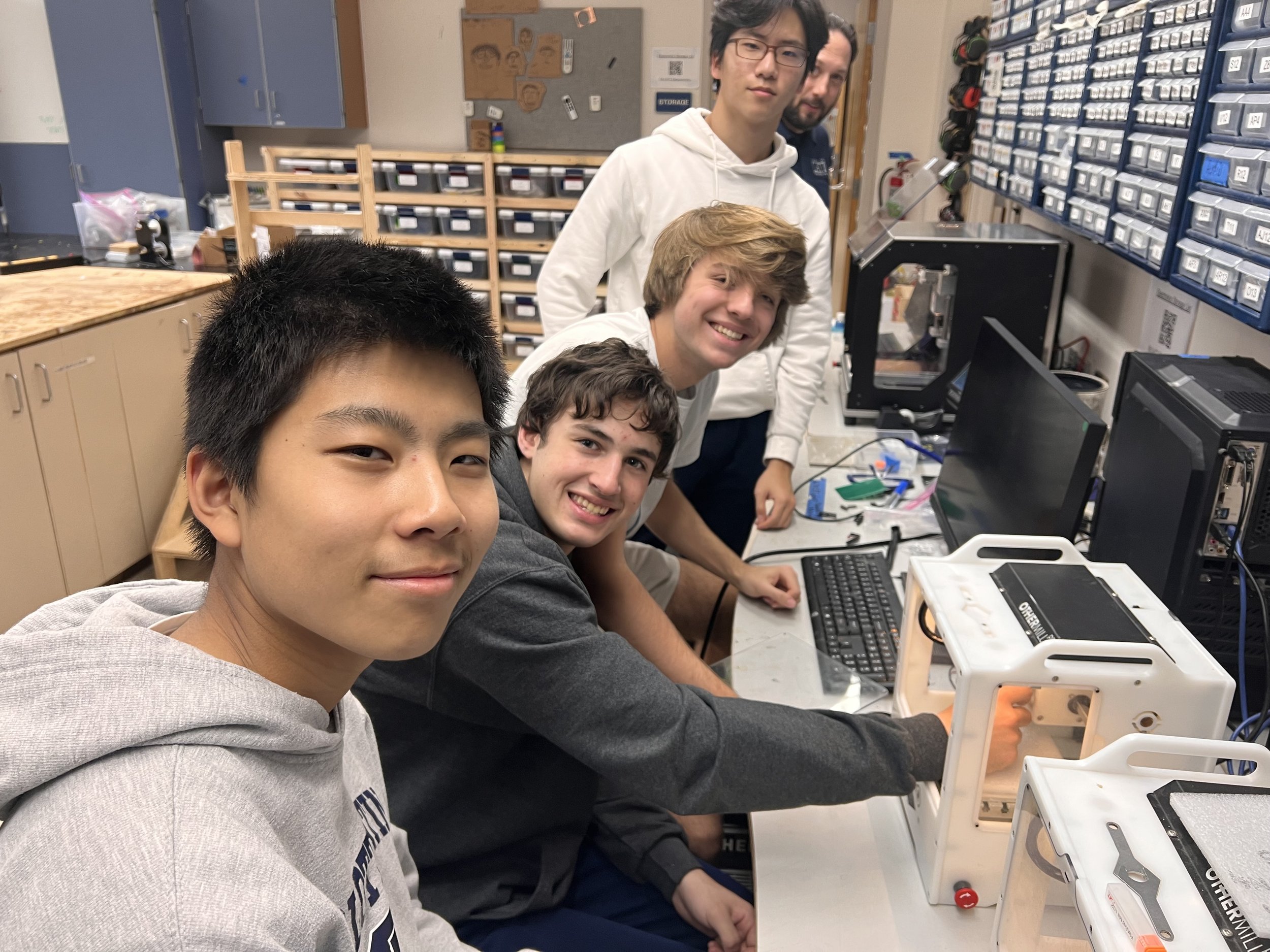

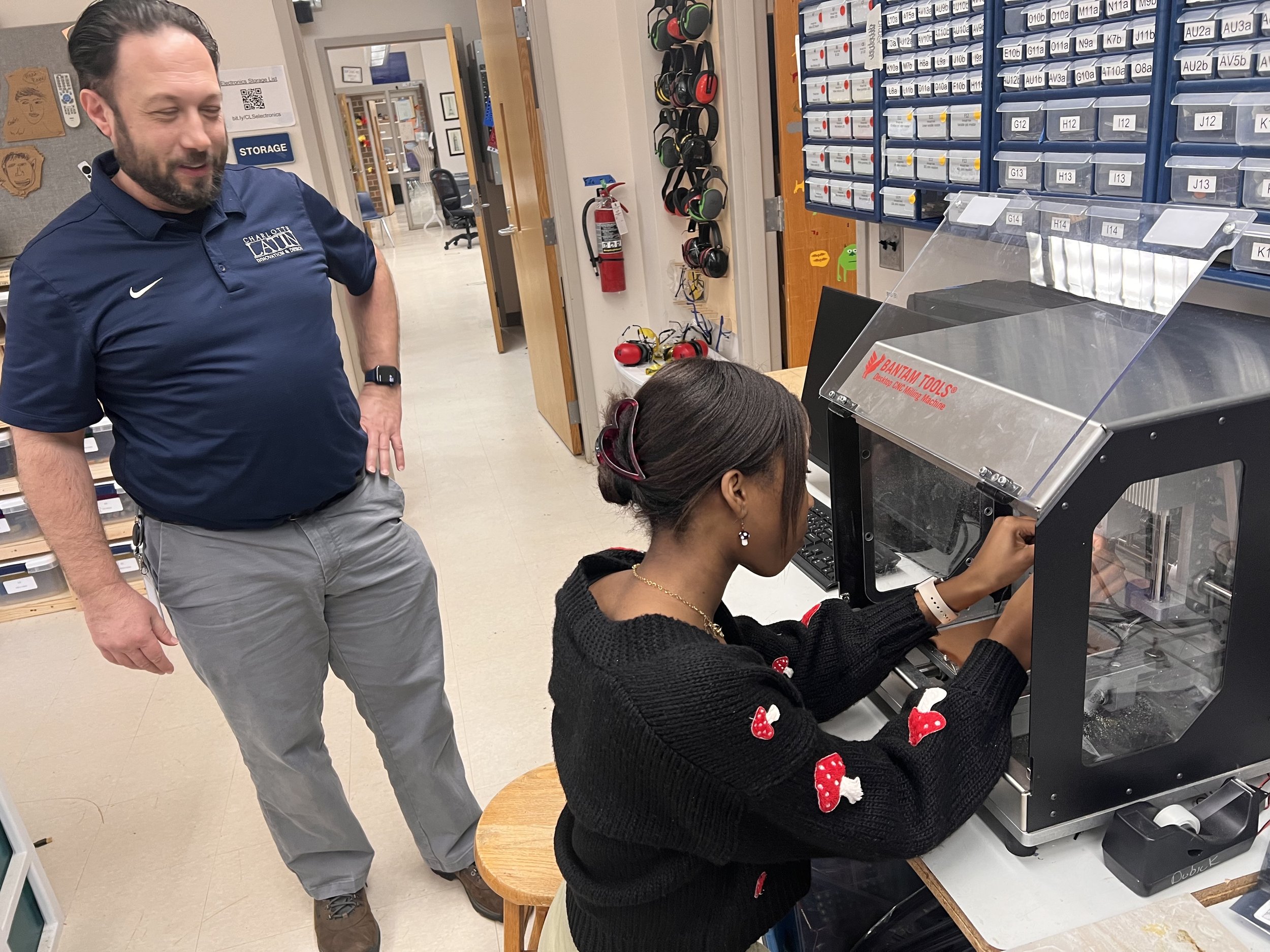

Students setting up a job on the Bantam Tools Desktop CNC Milling Machine,.

Known for its focus in college preparatory education, Charlotte Latin School runs a top-notch engineering program and is outfitted with a fully certified fab lab that offers students access to tools and knowledge that have the potential to accelerate their career in STEM or manufacturing. They have been long-time Bantam Tools Desktop PCB Milling Machine users and have added the Bantam Tools Desktop CNC Milling Machine to their space as well. Since we last spoke with them, the need for skill development in the manufacturing space has exponentially increased. To learn more about what’s new to the program and STEM education trends, we spoke with Tom Dubick, who founded the program in 1989 and brings over 30 years of education experience to the table.

Tell us about your background. What drove you to start the STEM program at Charlotte Latin?

I started our engineering program in 1989 after learning my students knew nothing about engineering careers. In fact, after mentioning engineering to a student, she responded that her parents did not want her to pursue a career in the railroad industry.

Our engineering (STEM) program always focused on the hands-on, practical application of math and science to solve problems and build projects. We always strive to balance academic rigor with student engagement. As a result, students will work very hard on projects they are interested in. Students will stay up late, live on pizza, and research technical esoteric subjects to make the best robot.

You’ve been running the fab lab at Charlotte Latin for over 30 years. Can you give us a quick snapshot of the goal of your program and what skills your students develop throughout it?

This is my thirty-fifth year of teaching and our fab lab officially opened in 2016. Today, our goal is to prepare students to be technology creators and not just consumers of technology. We want our graduates to have a firm foundation in the engineering method and be lifelong learners who can develop solutions to problems that don’t even exist today. Our students create digital portfolios to document their work and, most importantly, how they overcame setbacks and small failures. Today, we encourage our students to work in Co-Ops or internships with local and not so local manufacturers and businesses.

Your program seems to focus a lot on preparing students for college. What is the benefit of exposing students to CNC machining early on?

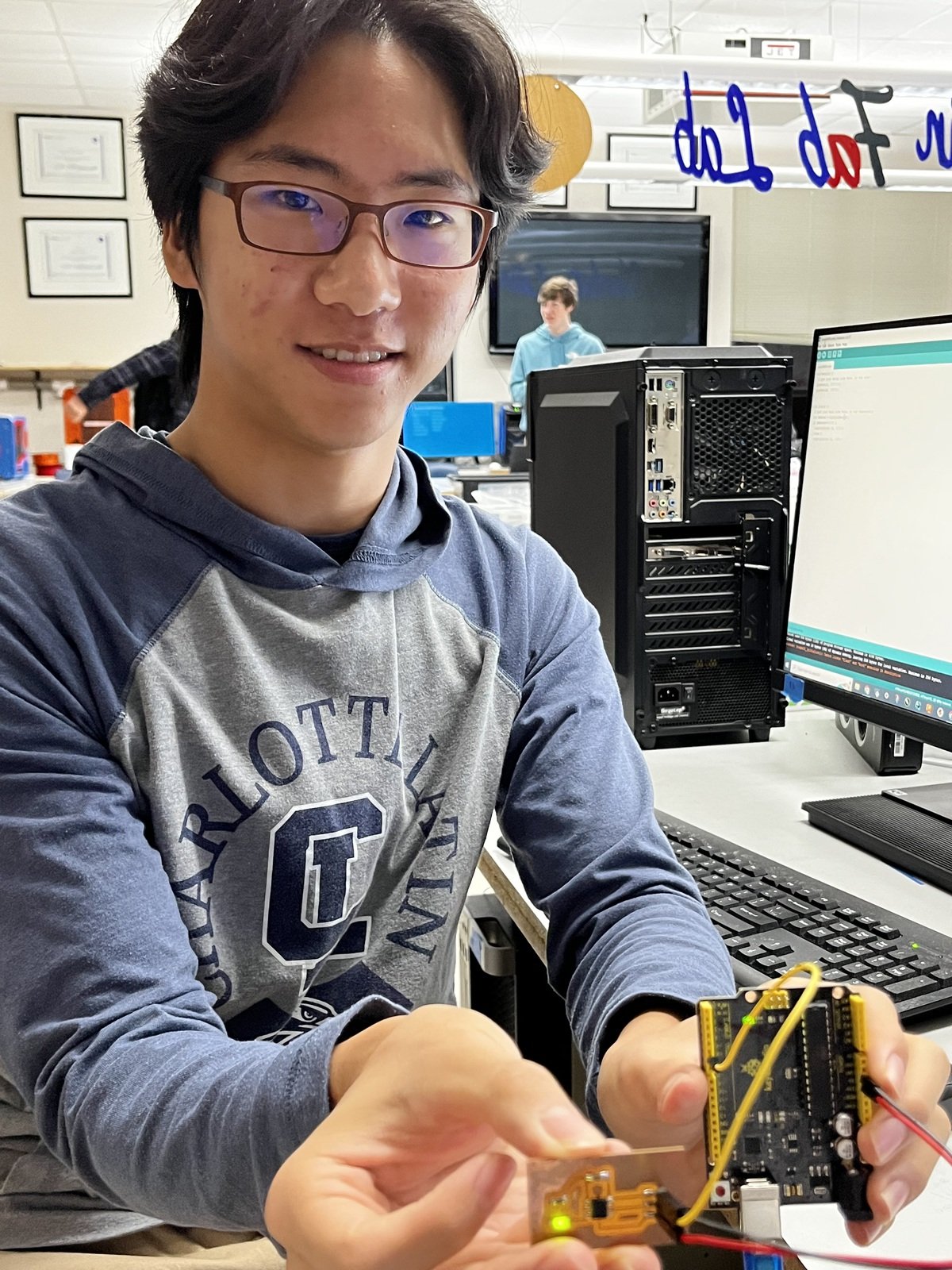

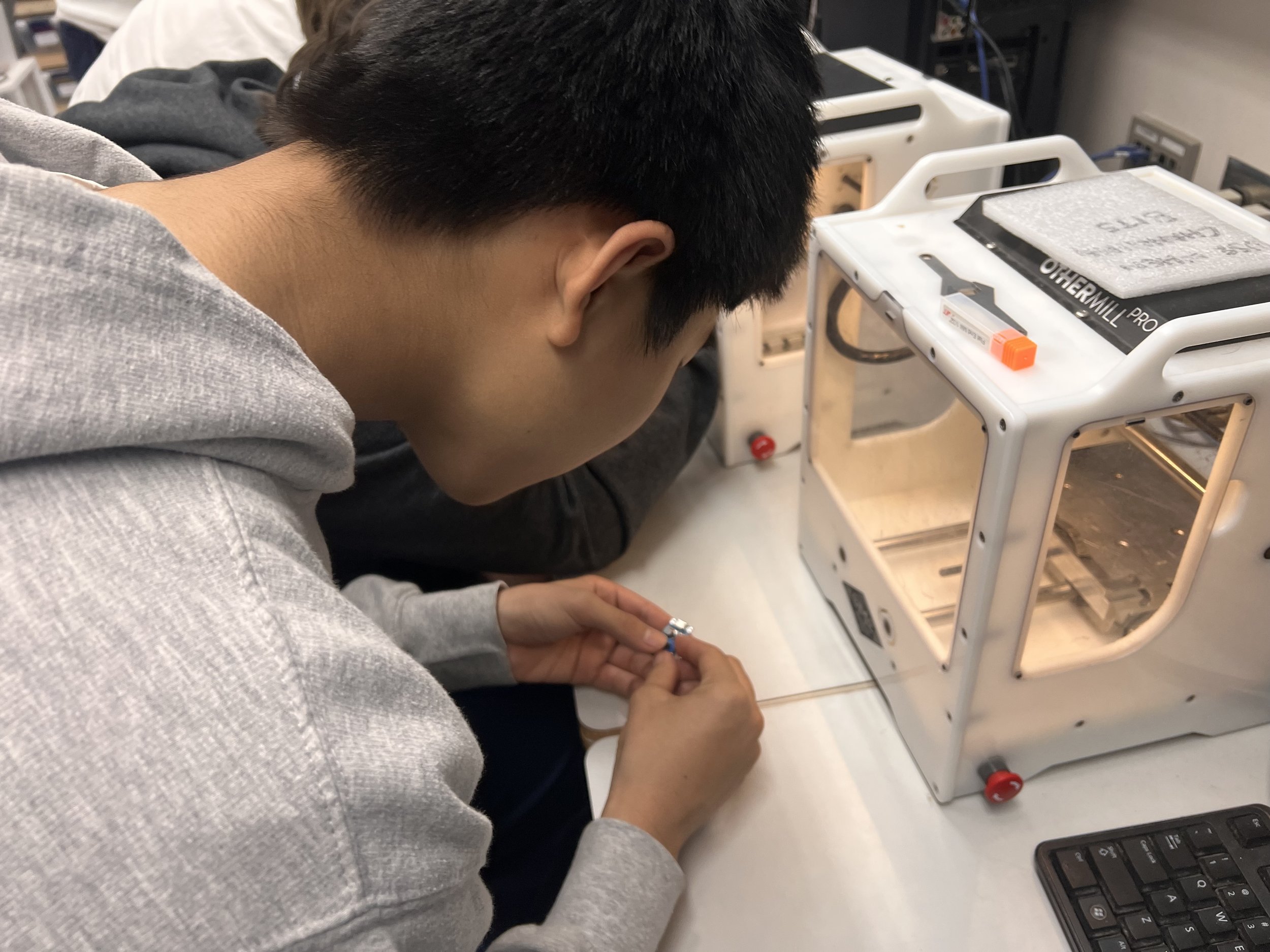

Students find CNC machining and its capabilities very captivating. Students get hooked using Bantam Tools milling machines, which leads them to explore CAD, CAM, and basic machining. We use the Bantam Tools machines primarily for making PCB boards, but we also use them for engraving, making molds, and custom projects. We rely on these machines to make our lab work.

Once students are accomplished in using these tools, they often want to build their own CNC machines from scratch. For example, we had three sophomores make a “pizza-making machine” that was a three-axis CNC machine with tool changing capabilities. They did their research and built and documented the machine without any help. All this work is excellent preparation for college and life beyond school.

How has the program evolved since we last spoke in 2015?

We (teachers) were stocking our fab lab and preparing to participate in Fab Academy. Back then, we offered Fab Academy to our teachers. Today, we offer Fab Academy to our students. We are the only high school in the world offering Fab Academy to students. Since we have a well-stocked fab lab and students who can use all the equipment, including the Bantam Tools machines, our students can work and bring value to local manufacturers and businesses.

What trends are you noticing in STEM education? Are there specific challenges you and your fellow educators are facing? What about your students?

Students should engage in the world outside the classroom as soon as possible. Students will gain the most from this experience if they can bring value to the companies, and training students on CNC machines certainly brings value. On the other hand, educators (at every level) should be speaking with businesses about the skills students will need to possess in the future to thrive in the future. Of course, companies need to help support educators through internships and Co-Ops. Our students will be working in jobs that don’t even exist today.

What specific steps should schools and companies be taking to develop their workforce?

Micro-credentialing, boot camps, and career-focused gap years should be options for all our students and adults. In addition, many adults would be interested in changing careers if they knew about the opportunities in the manufacturing sector, which is currently looking for workers.

About Charlotte Latin School

Charlotte Latin School is based in North Carolina and runs one of the 20 certified Fab Labs in the U.S., many of which are at colleges and universities. Latin’s Middle and Upper School engineering students work to solve real-world problems and create real-world products. Fab Lab participants share information with other Fab Lab locations around the world (via a live feed that is broadcast to other Fab Labs) and have opportunities to collaborate on projects with an international network of professional engineers, entrepreneurs, educators, and students.

For the latest Bantam Tools news, sign up for our newsletter. You can also follow us on LinkedIn, YouTube, Instagram, Facebook, or Twitter. If you’re interested in adding a Bantam Tools machine to your workflow you can order directly from our online store or request a quote.