Precision Tools Making Precision CNC Machines

Since we started manufacturing precise CNC machines back in 2013, keeping as much of our process in-house was important to our team. It’s allowed us to have more control over the development over our products and maintain a high level of quality. As our machine shop has grown, we’ve gotten a number of cool tools. But there are few metrology that have been part of our process from the start. Here are three metrology tools you can find in our shop.

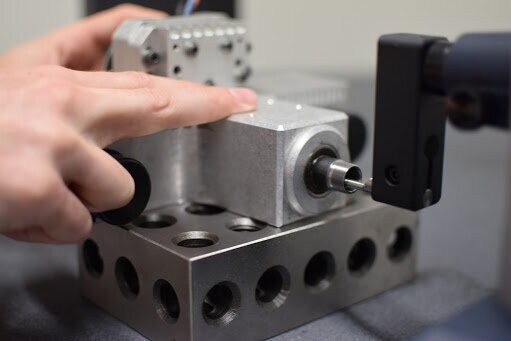

Mitutoyo Linear Height Gauge

The Mitutoyo linear height gauge is by far one of our favorite metrology tools. With an accuracy of 1.1+0.6L/600μm and 0.1μm/0.5μm resolution/repeatability, this tool utilizes air cushions and interchangeable probes that can be adjusted depending on the mode of operation we use. It can also measure straightness, displacement, and squareness. Plus, we use it to create customizable part programs that allow for semi-automatic measurements, which helps us save time when it comes to testing the Desktop CNC Milling Machine throughout the assembly process.

Digital Calipers

Measure twice, cut once. Whether we’re prototyping parts using the Bantam Tools Desktop CNC Milling Machine or Bantam Tools Explorer™ CNC Milling Machine, or prepping a job on one of our aerospace-grade Mazak Nexus 501Cs, we use digital calipers to measure our stock. Digital calipers like the Mitutoyo calipers shown below, guarantee accurate measurements up to ten-thousandths of an inch! In general calipers enable you to measure fit joins, stock thickness, and cutting depths.

Granite Table

This piece of metrology equipment often goes overlooked, but it’s literally the foundation for most of our team’s development, assembly, and testing processes. The granite plate is exactly what it sounds like: a huge chunk of rock. This plate is specifically designed to not distort and to hold up against wear and tear. But the most important aspect of the granite surface plate is that it’s completely flat, which ensures that when we’re measuring and testing, we’re working off a level surface.