Bantam Tools Solutions

*We are currently not taking any new Turnkey Solution Projects due to our Engineer staff being focused on new product development

Please check back here to see if we’ve been able begin taking on new projects.

*We are currently not taking any new Turnkey Solution Projects due to our Engineer staff being focused on new product development

Please check back here to see if we’ve been able begin taking on new projects.

We’ve been manufacturing our own wire harnesses, panels, and more in-house in Peekskill, NY, since 2020 to have more control over our supply chain. Work with our experienced team to avoid further to get your essential electromechanical components manufactured and stop fighting unpredictable supply chain delays.

What we offer:

Harness manufacturing

Panel manufacturing

Electromechanical production and assembly

Connect with our expert team and speak with us about the solutions your require.

Since 2013, we’ve manufactured precise and reliable desktop CNC machines for world changers and skill builders. This obsession with precision and communication with our clients is present in everything we do. Work with our team of knowledgeable and experienced engineers and machinists to frabricate quality parts you need throughout every phase of the manufacturing process.

Located in Peekskill, NY, our 12,000 ft. machine shop is outfitted with aerospace-grade vertical machines, 5-axis milling machines, lathe and turning, drill and tapping, and desktop CNC machines with 3-axis and 4th axis capabilities. Below is a list of machines in our shop:

Mazak Nexus 510C (2)

Haas Mini Mill

Haas VF-4SS

Bridgeport Series I mill with DRO

Nakamura-Tome dual turret lathe with subspindle

Brother TC-22B-O with 5th axis

Hardinge Lathe with DRO

Bantam Tools Desktop CNC Milling Machines

Bantam Tools Explorer™ CNC Milling Machines

The versatility of our machine shop and dedication to precision enables us to serve a number of industries. Our capabilities are best suited to serve the following industries:

Aerospace

Automotive

Consumer Products

Defense

Medical

Prototyping

Robotics

We have the capacity to work with a number of a different materials. We specialize in the following materials:

Aluminum

Brass

Engineering Plastics (e.g. Delrin, HDPE, ABS, Polycarbonate)

Steel

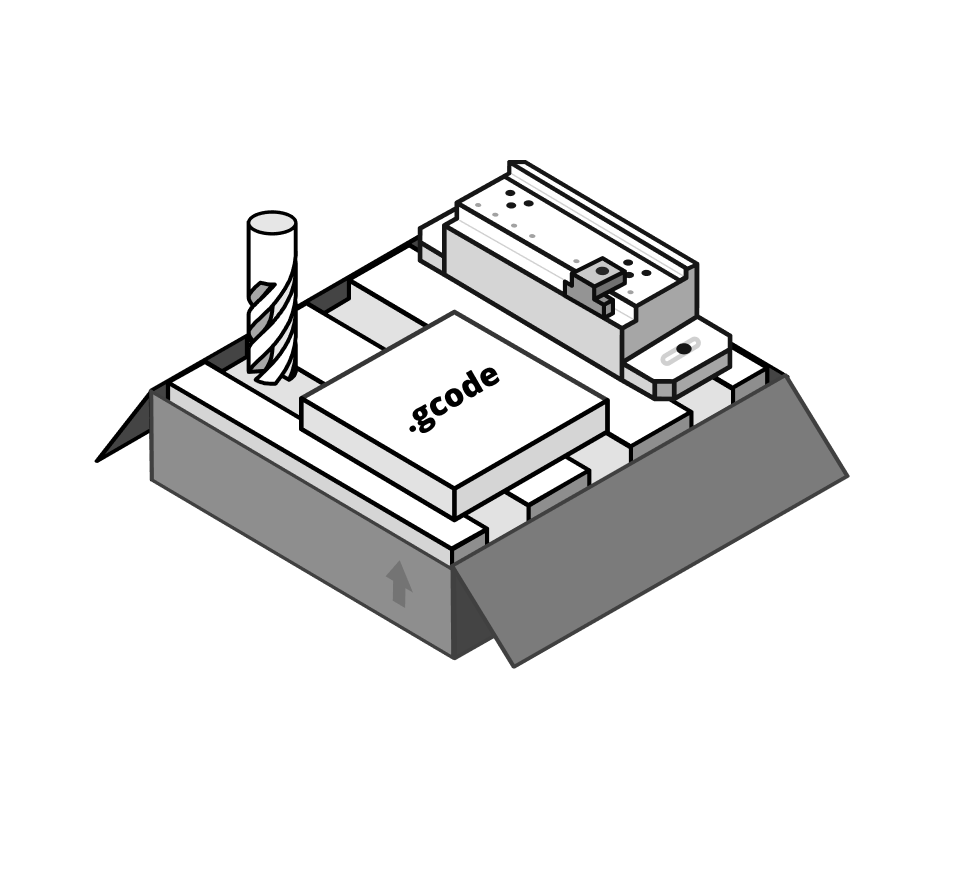

Bantam Tools Turnkey Solutions, gives you a proven process to make your design a physical part, as well as the confidence and the know-how to make more using Bantam Tools milling machines. This is an ideal solution for engineers, product designers, and manufacturers who need a reliable process immediately.

Step 1

Submit a request below, outlining the part(s) you need to make using the Bantam Tools Desktop CNC Milling Machine.

Step 3

After an agreement has been reached, expert Bantam Tools engineers will create and document a process for machining your part on the Bantam Tools Desktop CNC Milling Machine.

Step 2

The Bantam Tools team will evaluate your request. If the machine is capable of machining the part, we will send you a quote with pricing, deliverables, and more that outlines the scope of work.

Step 4

Once our experts have machined the part and developed a process using the Bantam Tools Desktop CNC Milling Machine, we will put together a turnkey package.

The Bantam Tools Desktop CNC Milling Machine has a 7” x 9” x 3.5” build volume.

The tightest tolerance the Bantam Tools Desktop CNC Milling Machine can hold is +/-.001".

Once you submit a request, our goal is to respond within 2-3 business days. Our hours of operation are Monday through Friday from 9 am to 5 pm EST.

Of course! We understand the parts you are developing may be proprietary and we will work with you to protect this information.

The final package we deliver will depend on your parts. Packages may include:

* Work instructions for how to set up and run your job

* Fusion 360 file with vetted CAD model and CAM toolpaths

* .BTP file that saves the job setup in the Bantam Tools software

* G-code files that were exported from the Fusion 360 file

* Expertly engineered custom fixturing (either designs or fabricated)

* The finished part

* Suggested machine tooling and accessories used to mill the part

Note: All deliverables are specifically created for the Bantam Tools Desktop CNC Milling Machine and the Bantam Tools Milling Machine Software.

Bantam Tools Solutions offers precision machining, harness assembly, electromechanical manufacturing, and turnkey engineering solutions. We take pride in customer communication.